Single Acting Cylinder Vs Double Acting Cylinder | Retraction happens through internal spring. A single acting cylinder has only an a port. Double acting cylinder is considered to be as a main actuator in any pneumatic systems. These are basically two different kinds of cylinders used for linear actuators. Single acting cylinders provide force to operate in one direction and depend on gravity (or a spring) to retract.

The single acting cylinder in figure 1.7 can be operated by two different circuits. Choosing between the single acting and double acting actuator depends upon your purpose. Which one should i choose? Fail condition of the valve plays and major role in selection. View answer / hide answer.

Which one should i choose? Alibaba.com offers 1,592 single acting and double acting cylinder products. Single acting cylinder only extends by pressure from a pump and then retracts by the weight of the load or by an inbuilt spring. With a single line, the hydraulic cylinders are your best bet when you are looking to source enormous power. A double acting cylinder uses hydraulic power to both extend and retract. Pressure drop, the difference between two pressure levels in a hydraulic circuit. Single vs double acting piston seals. A single acting cylinder has only an a port. A single acting pneumatic cylinder is a linear actuator and realizes a working stroke by filling the cylinder with compressed air. They have two ports to allow air in, one for outstroke and one for instroke. Double acting cylinder is considered to be as a main actuator in any pneumatic systems. Linear actuator cylinders single acting double acting— presentation transcript 2 pump vs actuator pump which convert mechanical input into fluid power output. I think you are asking why most plow set ups have 2 single asting cylinder, why not just 1 double acting on 1 side.

For large single acting or double acting cylinder we prefer to use direct control. 13 produces linear motion in one direction consists of cylinder. Pneumatic solenoid valve's operating principle, types, sizing, and selection are discussed. A wide variety of single acting and double acting cylinder options are available to you, such as condition, local service location, and applicable industries. Single acting cylinders provide force to operate in one direction and depend on gravity (or a spring) to retract.

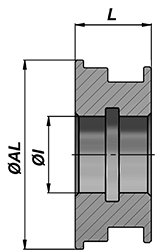

With a single line, the hydraulic cylinders are your best bet when you are looking to source enormous power. Hydraulic telescopic cylinders vary from not telescopic cylinders in that they only require a very smallamount. The relation of cylinder force, bore size and operating pressure is the following. Double acting cylinders are more expensive than single acting cylinders, but double acting cylinders are superior to single acting cylinders by many other important measure. For large single acting or double acting cylinder we prefer to use direct control. When selecting a cylinder for an application, remember that a double acting. In this video, we will explain the difference between a single acting hydraulic cylinder and a double acting hydraulic cylinder. Cylinder pushes in both directions, while a single acting cylinder. Retraction happens through internal spring. Single vs double acting cylinders: Single action is a control valve that is driven by the air output of the control valve positioner on one side while the other side is moved with the aid of a spring or a membrane. Zetor 86 41 forterra turbo manual online: Double acting cylinders with single rod have a piston rod which is connected rigidly to a piston rod which has a diameter smaller than that of the piston.

Double acting cylinder is considered to be as a main actuator in any pneumatic systems. Pneumatic solenoid valve's operating principle, types, sizing, and selection are discussed. Piston seals are used to create a seal between the piston and the cylinder bore single acting piston seals contain pressure on one side of a piston without leakage. Linear actuator cylinders single acting double acting— presentation transcript 2 pump vs actuator pump which convert mechanical input into fluid power output. A single acting pneumatic cylinder is a linear actuator and realizes a working stroke by filling the cylinder with compressed air.

This allows maximum effort to be applied to moving the piston. Hydraulic telescopic cylinders vary from not telescopic cylinders in that they only require a very smallamount. Advantages of single acting hydraulic or pneumatic cylinders. In this video, we will explain the difference between a single acting hydraulic cylinder and a double acting hydraulic cylinder. For large single acting or double acting cylinder we prefer to use direct control. Double acting cylinder is considered to be as a main actuator in any pneumatic systems. Retraction happens through internal spring. Cylinder pushes in both directions, while a single acting cylinder. Single vs double acting piston seals. Alibaba.com offers 1,592 single acting and double acting cylinder products. Fail condition of the valve plays and major role in selection. Choosing between the single acting and double acting actuator depends upon your purpose. Double acting cylinder can be used as a single acting cylinder.

Single vs double acting cylinders: single acting cylinder. In the case of the extension side, theoretical output of single acting cylinder is a value taken secondary mounting load of the spring off.

Single Acting Cylinder Vs Double Acting Cylinder: Although both systems use compressed air as their main source of energy, their port design allows them to perform quite differently.

0 Komentar:

Posting Komentar